Preclinical

Production of related substances and samples

We support research such as synthesis study of samples (FTE basis).

Kyowa Pharma Chemical manufactures APIs, compounds in the early stages of development, and APIs for clinical studies by using our unique chiral technologies such as enzyme reaction, asymmetric synthesis, and optical resolution methods.

In order to ensure a stable and continuous supply of high-quality APIs, we devote our total manufacturing technologies (including the design and engineering of production facilities) to establish each plant. The production systems at multi-purpose plants rationalize and optimize the process of each product, and allow us to handle large-volume batch production to low-volume production and multi-items production. Our production facilities that are rich in variety can handle a wide range of production scales. We establish flexible production systems with these facilities, and these have been well-received by a lot of our customers.

Furthermore, we have established a management system in accordance with GMP (Good Manufacturing Practice) and global quality standards.

We can respond to a wide range of customer requirements in terms of quality and pharmaceutical regulatory affairs.

We offer total support from early R&D to the commercial stage.

We support research such as synthesis study of samples (FTE basis).

We manufacture APIs for clinical studies using gram-scale manufacturing equipment.

We have extensive experience in the process of developing complex

and highly potent small molecules (e.g., Prostaglandins).

We have systems conforming to US, EU, and Japan GMP requirements.

We have achievements in process improvement using Bioconversion methods.

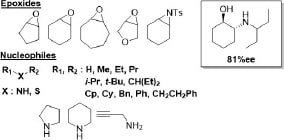

We have several patents. Our flexible technology enables support from the early stages of development.

In addition to patents related to the synthesis process, we also have our own unique patents.

Patent #: 6630667: PROCESS FOR PRODUCING OPTICALLY ACTIVE SUBSTANCE

Heat resistance : Remains active at 100° C

Recycle : Possible (Regeneration treatment is NOT needed)

Physical property : Non-soluble in organic solution (Easily separable by filtration after the reaction)

We have a production system with comprehensive manufacturing technology, high efficiency, and environmental protection at the same time. In order to provide a stable and continuous supply of high-quality products that meet our customers' requirements, we establish plants with total manufacturing technology, including engineering technology.

| Plant A | |||

| Manufacturing products |

APIs and Intermediates | ||

| Lot size | up to 50 kg | ||

| Major facilities | Manufacturing area | Reactor |

10L, 20L, 50L [Glass flask] 100L, 200L, 500L, 600L, 800Lx2, 1600L, 2000L [GL] 50L, 100Lx2, 200L, 500Lx2, 1200Lx2, 1500Lx2 [SUS] |

| Silica gel column | 30L, 40L, 150L, 250L, 350L, 500L [SUS] | ||

| Flash evaporator | 10L x 2, 50L x 2 [Glass] | ||

| Rotary evaporator | 10L, 20L x 4 [Glass] | ||

| Centrifuge | 30B [SUS], 30B [Hastelloy], 36B [Hastelloy] | ||

| Conical dryer | 400L[GL] | ||

| Controlled room | Two rooms | ||

| Rotary evaporator | 1L x 3, 10L x 2 | ||

| Flash evaporator | 50L x 2 [Glass] | ||

| Lyophilizer | 40L/ batch | ||

| Plant B | |||

| Manufacturing products |

APIs and Intermediates | ||

| Lot size | up to 30 kg(300-500L) | ||

| Major facilities | Manufacturing area | Reactor |

340L (-80~120℃) [GL] , 500L (-30~120℃) [GL], 340L (-30~120℃) [GL] , 300L (-30~120℃) [SUS] |

| Portable mixing tank | 100L x 3 [SUS] | ||

| Portable tank | 200L x 2 [SUS], 200 L[Hastelloy] | ||

| Filter | 0.3m2 [SUS] x 2, 0.5m2 [SUS] | ||

| Vacuum shelf dryer | 3m2 [SUS] | ||

| Milling machine | Possess | ||

| Controlled room | Two rooms | ||

| Reactor | 300L (-25~120℃) x 2 [SUS] | ||

| Filter dryer | 0.3m2 [SUS], 0.3m2 [Hastelloy] | ||

| Plant C | |||

| Manufacturing products |

Intermediates | ||

| Lot size | up to 800 kg(3,000-10,000L) | ||

| Major facilities | Manufacturing area | Reactor |

3000L, 9200L, 10000L [GL] etc. 3000L, 6000L, 10000L [SUS] etc. |

| Reduction reactor | 4900L [GL] , 5000L [SUS] | ||

| Filter dryer | 1700L [SUS] | ||

| Centrifuge | 48B [Hastelloy] , 48B[SUS] | ||

| Conical dryer | 4000L [GL] | ||

| Plant D | |||

| Manufacturing products |

APIs and Intermediates | ||

| Lot size | up to 30kg(10-800L) | ||

| Major facilities | Manufacturing area | Reactor |

10L, 20L [GLASS] 200L, 200L, 800L [SUS] 500L, 800L [GL] |

| Filter | 20L, 70L, 120L [SUS] | ||

| Conical dryer | 450L [SUS] | ||

| Portable column | Possess | ||

| Flash evaporator | 50L | ||

| Rotary evaporator | 20L x 2 | ||

| Controlled room | Crystallization tank (Kilolab) |

20L, 50L | |

| Filter dryer | 20L x 2[SUS] | ||

| Flexible isolator | Possess | ||

| Plant E | |||||

| Manufacturing products |

APIs and Intermediates | ||||

| Lot size | up to 800 kg(3,000-8,000L) | ||||

| Major facilities | Manufacturing area | General Work Area Zone1 | General Work Area Zone2 | ||

| Reactor |

8000L×2 [GL] 8000L [SUS] |

Reactor |

8000Lx2 [GL] 6000L [SUS] |

||

| Dissolution tank |

3000L, 5000L [GL] 3000L [SUS] |

Dissolution tank | 5000L x2 [GL] | ||

| Agitation tank | 6000L×2 [GL] | Agitation tank | 6000L [GL] | ||

| Centrifuge | 48B [Hastelloy] | Centrifuge | 48B [Hastelloy] | ||

| Conical dryer | 4000L×2 [GL] | Conical dryer | 4000L [GL] | ||

| Purified water manufacturing facility |

Possess | Purified water manufacturing facility |

Possess | ||

| Controlled room | Reactor | 8000L [GL] | |||

| Centrifuge | Φ1000 [Hastelloy] | ||||

| Conical dryer | 4000L [GL] | ||||